Lightweight 3D Printed Knee Brace Gives Grandparents A Leg Up

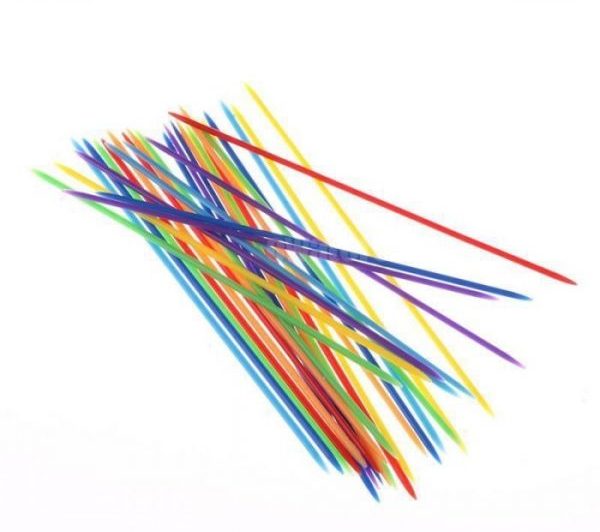

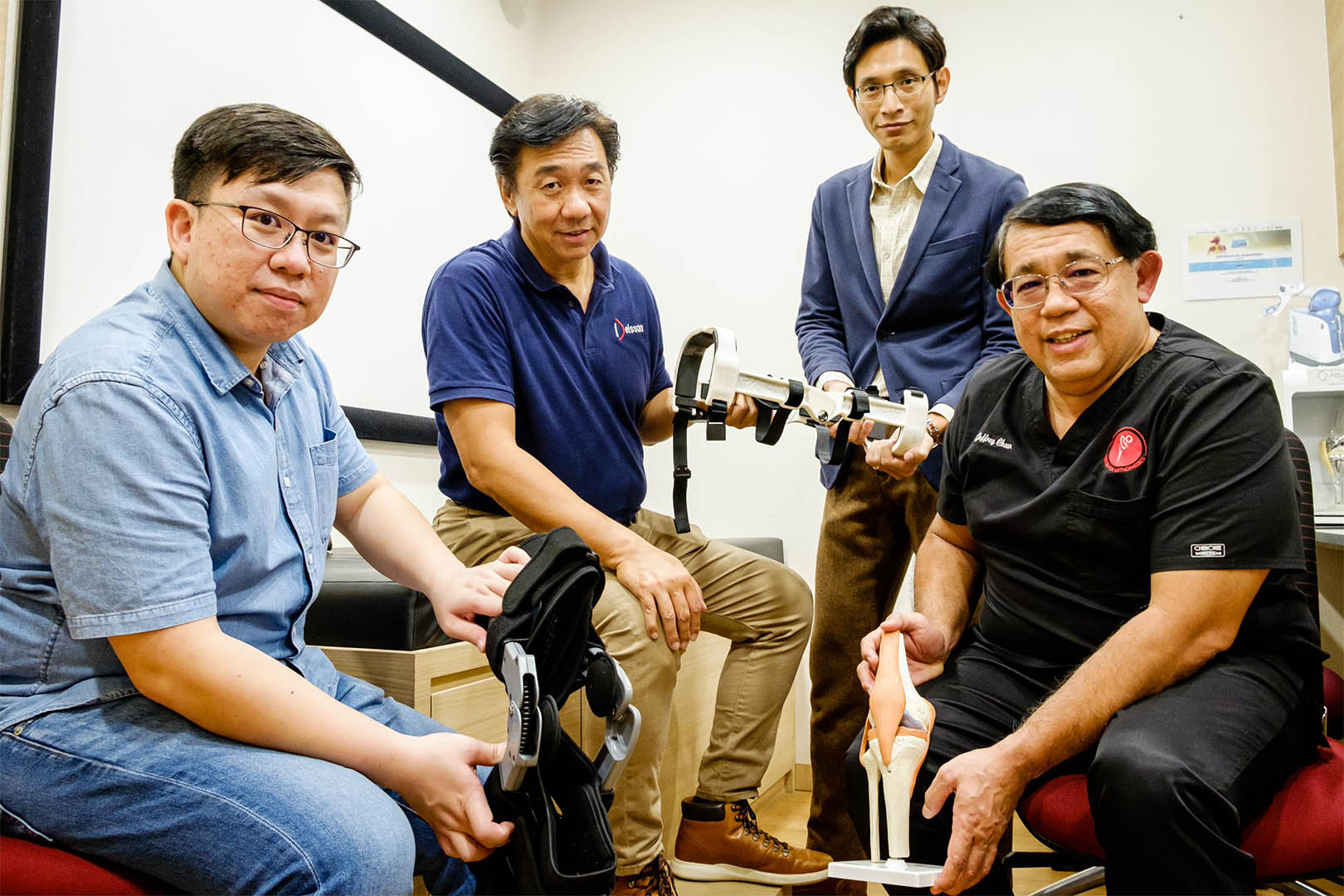

Knee braces can be heavy, unwieldy, and hard to walk in, especially for the elderly. But in December 2021, in collaboration with 3D printing specialists from Nanyang Technological University (NTU Singapore), Singaporean engineering firm Delsson unveiled the X-Brace, a lightweight 3D-printed knee brace suitable for seniors who suffer from chronic knee pain. Patients who have undergone knee replacement surgery can also use the 3D-printed knee brace, which – unlike conventional knee braces, which restrict movement of the knee – allows patients to recover by exercising their knee after surgery.

So how does it work? At 720 grams, the X-Brace is 30 percent lighter than its metal counterparts, which typically weigh over 1 kilogram. It’s also customisable: by adjusting the springs, doctors and physiotherapists are able to tweak the amount of assistance given by the brace, enabling patients to recover at their own pace. For the elderly, this makes pain management and active recovery a more viable option – the brace alleviates the burden on their joints while allowing them to still climb stairs or walk to the nearby market for errands.

While designing the brace was a team effort, the project’s design efforts were led by none other than Joel Lim, a 33-year-old PhD student at NTU. Along with NTU Assistant Professor Chan Wai Li, Joel Lim worked to understand his client’s problems – such as the heaviness of knee braces – and used a stress map and 3D modelling to figure out how to design a knee brace that could allow knee mobility while helping it move in the right direction.

As futuristic as the X-Brace sounds, Joel’s interest in 3D printing actually began in 2007, when he was an intern doing projects for the National Additive Manufacturing Innovation Cluster (NAMIC). During his time there, he learnt how 3D printing can help you make products with less parts, “thus saving on assembly cost, material required for assembly, and reducing uncertainty in parts.”

Joel’s time in National Service also inspired him to do what he can to improve others’ physical wellbeing.

“I served in the Transport Hub (TPT HUB) West as an ambulance driver, so I understand the urgencies of making sure that we save lives, or make lives better. Therefore, [working on projects now] sent me on a trip down memory lane….The things we made, using 3D printing can be helpful towards making lives better.”

We caught up with Joel amidst his busy schedule to find out what inspired the team to use innovative technology to help the elderly, as well as the challenges that went into creating the X-Brace.

Why did the team decide to focus on making a knee brace for the elderly, in particular?

Singapore is facing an aging population and it is a market that will grow over time. We do want our elderlies to be able to move about and I feel that the knee brace is a start of a concept that hopefully will have other companies to look into improving the lives of our elderlies. It is thanks to their hard work years ago, building Singapore, [that we have what] we have today.

How did you become involved in the project with Delsson?

It started with a Whatsapp message from the NAMIC MD, Dr Ho Chaw Sing. I decided to take on a challenge to see how or what we can do to further reduce the weight of the object....My PhD Prof, Prof Chan Wai Lee has been guiding the team throughout the entire project after to ensure that it meets its success. He even tried on the leg brace!

What kind of challenges did you and the team encounter?

Most of the time we have to be on site to do the physical printing, assembly, testing etc. Sometimes it is difficult to be in the office daily due to the WFH requirements. The team overcame this by having various people doing the printing, monitoring and part removal schedule depending on who is in for the day.

Some other issues were supply chain related, but good vendor relations help us in the long run to secure the required materials for printing.

What are some memorable moments/stories you’ve gleaned from this whole experience?

Well, one was that we managed to reduce the weight significantly and make sure that the part is strong and stiff. Also seeing the product as it comes from a CAD model (in the computer) to an actual part is always very exciting.

What else could 3-D printing be used for, in terms of helping the elderly in Singapore?

Many things, in fact! It comes down to what they need, and how customised they can be. 3D printing is also a very good technology for rapid prototyping. Things ranging from parts repair or replacement for their current tools i.e. wheelchairs, PMAs, etc. Ultimately it is up to one’s imagination to create products to help the elderly, and the tool to deliver this product is 3D printing!

Do you have grandparents/elderly folks in your life? How much do they know about this project that you were working on, and have they said anything about it?

My grandparents were not aware as we usually do not speak about projects we done due to NDA. But well now it is announced I guess I’ll let my grandmother know!

The X-Brace is distributed by Wearable Kinetics, a subsidiary company of Delsson, and available at SGD$1,000 (US$782), with the price subject to the user’s desired configuration.

The Centre for Orthopaedics is currently the only medical clinic that is trained to examine and prescribe the use of the X-Brace.

For the latest updates on Wonderwall.sg, be sure to follow us on Facebook, Instagram and Telegram. If you have a story idea for us, email us at [email protected].